Field Services

Apache and the Mepaco group have a dedicated department of field service professionals. Production uptime is our top priority to help customers with commissioning, ramp-up, maintenance, repair and emergency breakdown support.

We provide experienced and proficient industry technicians and engineering support to perform services, including:

- Field service and troubleshooting to all types of stainless and high alloy tanks

- ASME / National Board R-Stamp repair and modifications

- Surface finish repairs

- Non-code repairs and modifications including piping and heat transfer jackets

- Seal and agitation repairs and modifications

- Accessory repairs

- Head and tank shell repairs

- Leak detection

- Audit and service contract available

Contact Josh Schladweiler

Field Services and Parts Manager

Cell (920) 344-1465

Quality Assurance

An important part of Quality Assurance is the process of manufacturing a vessel to meet compliance specifications and the testing and certifications to support those standards.

Apache Stainless has a dedicated quality assurance department that focuses on full verification, testing and documentation of compliance. Our welders and inspectors are ASME certified and as a company, Apache has been ASME certified since 1975.

Testing

- Pneumatic

- Hydrostatic

- Liquid Penetrant

- Saline

- CIP Coverage

- Base Metal Thickness

- Ferroxyl

- Positive Material Identification (PMI)

- Ferrite Levels

- Radiography

- UT Testing

Processes

- Material Trace

- Welder Trace

- Pickling

- Passivation

- Electropolishing

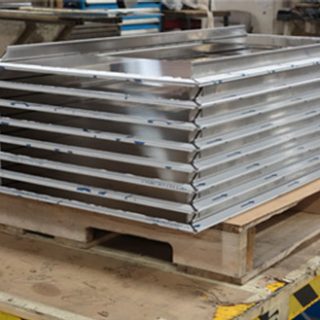

Contract Manufacturing

Apache’s Contract Manufacturing group provides design, support and fabrication solutions for custom metal parts and components to a variety of industries.

Our in-house passivation and electropolishing services allow Apache to provide all-inclusive control over the fabrication and stainless finishing process providing expedient project turnaround.

Services include:

- Assembly

- Custom Fabrication

- Gantry Drilling

- Laser Cutting

- ASME Certified Welding

- Stainless Finishes

Metal Finishing

Apache Stainless Equipment Corp. offers in-house finishing, including pickle passivation and electropolishing services.

Pickle passivation is the immersion of metal in a nitric-hydrofluoric acid bath. Pickled stainless material has a light matte appearance. Benefits include ease of sterilization and corrosion resistance.

Electropolishing is the immersion of metal in a charged bath of sulfuric and phosphoric acid. Benefits include ease of sterilization, improved cleaning properties, corrosion resistance, and a mirror finish look.

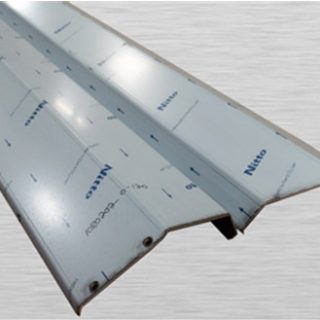

Transport

Since 1976, we have provided general transport as well as specialized, high and heavy load transport. Our air-ride tractor trailers are operated by conscientious employee-owners who take pride in careful and expedited cargo handling.

Our transportation capabilities include:

- Air ride tractors with direct-transport door-to-door service

- Specializing in oversize and super loads

- Apache will provide necessary permits, escorts, route surveys, bucket trucks and communications for your transport needs.

- Apache Transportation offers full loads as well as partial loads (LTL) to meet your transportation needs.

- We have annual permits for our tractors, which allow us to handle oversize loads without the need for permits for every trip, eliminating permitting delays.

- Boat wrapping available by request

- TWIC: All drivers are TWIC certified

- Perfect DOT Safer rating