Custom vessel manufacturing to industries requiring compliance is what we do. There is a process for customer service and engineering that is required to get the custom vessel you require for your application. Numerous specifications will be required based on your process or level of compliance. Apache will work with you to explain and provide options for your vessel project. This collaborative effort will have to control costs and expedite timing for your custom vessel.

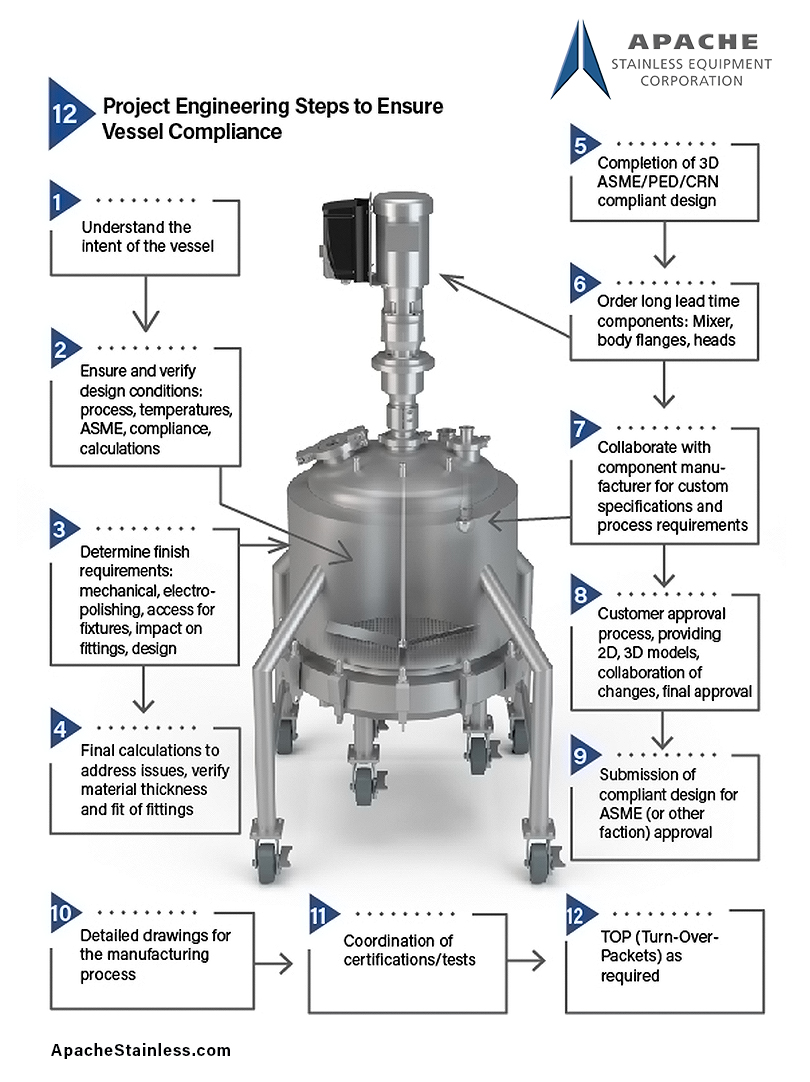

Here are our 12 Project Engineering Steps to Ensure Vessel Compliance:

- Understand the Intent of the Vessel. Apache has 45 years of experience manufacturing custom vessels. We can lead important project planning discussions if we know the intent or type of process in which the vessel will be used.

- Ensure and Verify Design Conditions. At this step, our project engineers look at the design conditions, process, temperatures, ASME, and other compliance requirements and perform initial calculations.

- Determine Finish Requirements. Once the design is verified and viable, the project is examined for mechanical and electropolishing requirements, as well as access needed for fixtures and how that has an impact on the fittings.

- Final Calculations. In this step, the engineer provides final calculations to address issues, verifying material thickness and fit of fittings.

- Completion of Compliant Design. The ASME/PED/CRN-compliant design is completed in 3D Solid Works.

- Order Long Lead Time Components. The long lead time components such as the mixer, body flanges, and heads are ordered. The supply chain is monitored carefully for timing, and any changes are communicated that may affect delivery.

- Component Manufacturer Collaboration. Apache leverages long-term relationships with component manufacturers to customize specifications to meet the needs of the process.

- Custom Approval. The customer receives approval drawings with 2D and 3D models. There is often a series of collaborative meetings to finalize the design and approval.

- ASME (or other faction) Submission. The final design is submitted for ASME or other compliance agencies for approval. Apache also leverages long-term relationships with regulatory agencies to help facilitate a smooth process.

- Detailed Drawings. The engineering team completes the detailed drawings for the manufacturing process and fabrication can begin.

- Tests / Certifications. ASME tests are scheduled and performed by our Quality Assurance team to comply with the certifications required for the vessel.

- Turn-over Packet (TOP). The documentation packet can be completed after the vessel is manufactured and the TOP is developed and uploaded to our customer portal.

Apache’s engineering team articulates technical discussions and is open with timelines, cost and compliance-related issues. Our competence for a pharmaceutical or life science industry vessel is strongly supported in providing all compliance-related deliverables.