Versatility of Dimple Jacket Heat Transfer Thermal Processing

Apache’s engineers and fabrication experts are entrusted by many national and international processors to provide complex vessels with a host of compliant-driven specifications and required quality protocols. With nearly 45 years of experience providing custom vessels, Apache has significant experience in thermal heat exchange surfaces.

Heat exchange surfaces can be designed for heating or cooling. Jacketed vessels are used in many industries and can be used to remove the elevated heat of reaction (heat reactor vessel) or reduce the viscosity of highly viscous fluids.

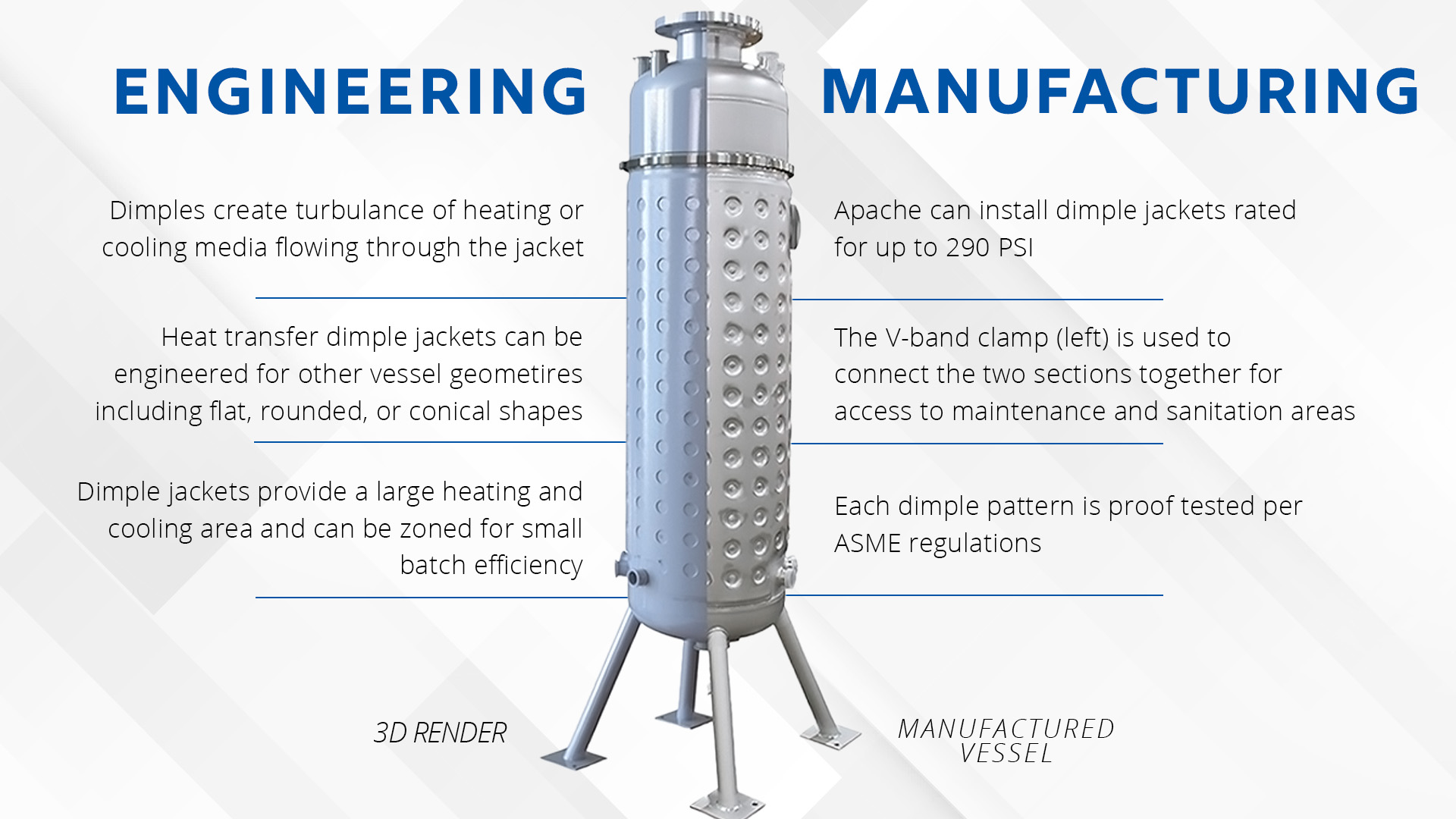

Depending on the application, dimple jackets offer versatility in heating or cooling for almost any shape or size of vessel.

Dimple jackets are constructed with a thin gauge stainless steel layer that is plug-welded to the vessel shell in a pattern. The punched and spot-welded areas are called dimples, which create turbulence of the heating or cooling fluid flowing through the jacket. The dimple jacket design allows for thinner vessel shell walls compared to a convention jacket due to the strength of the dimple pattern design.

Dimple Jackets are manufactured in several different pressures and patterns. Apache provides both 12 ga. and 14 ga. material. Each pattern is validated and proof-tested per ASME regulations.

Apache has proofed and certified designs up to 1 ¾” at 290psig at 300o F but can go to higher temperatures depending on the application.

Applications and Features

- ASME approval by the National Board of Boiler and Pressure Inspectors up to 290 psig.

- Pressures of 290 psig with temperature limited to 500 degrees F, depending on the application.

- High jacket pressures permitted without significant increase of side structure thickness.

- Efficient heat transfer at low media flow.

- Dimple jackets are well suited to steam applications.

- They can be used to provide heat transfer or cooling for virtually any shape or size of vessel.

- On large tanks, dimple jackets have a lower price point and maintain a higher pressure drop compared to conventional jackets. On small vessels, conventional jackets have a lower price point followed by dimple jacket and half pipe solutions

Apache specializes in manufacturing custom vessels for high-compliance industries including pharmaceutical and bio-pharma. We manufacture specialty sanitary design tanks, including pressure vessels, processing tanks, and mixing vessels. We have all Stainless ASME certified manufacturing facilities with custom capabilities including heat exchange surfaces, agitation, CIP (clean-in-place) componentry and controls. Apache has an in-house quality and compliance team to provide all testing and documentation requirements.

Learn more about Heat Transfer.