As the Cannabis Processing industry continues to evolve, increasing regulations are following. With continuous new products and additive combinations entering the market, the sale and distribution of the products will have more regulations. The processing and production of CBD and cannabidiol components are already seeing increasing standards.

As the Cannabis Processing industry continues to evolve, increasing regulations are following. With continuous new products and additive combinations entering the market, the sale and distribution of the products will have more regulations. The processing and production of CBD and cannabidiol components are already seeing increasing standards.

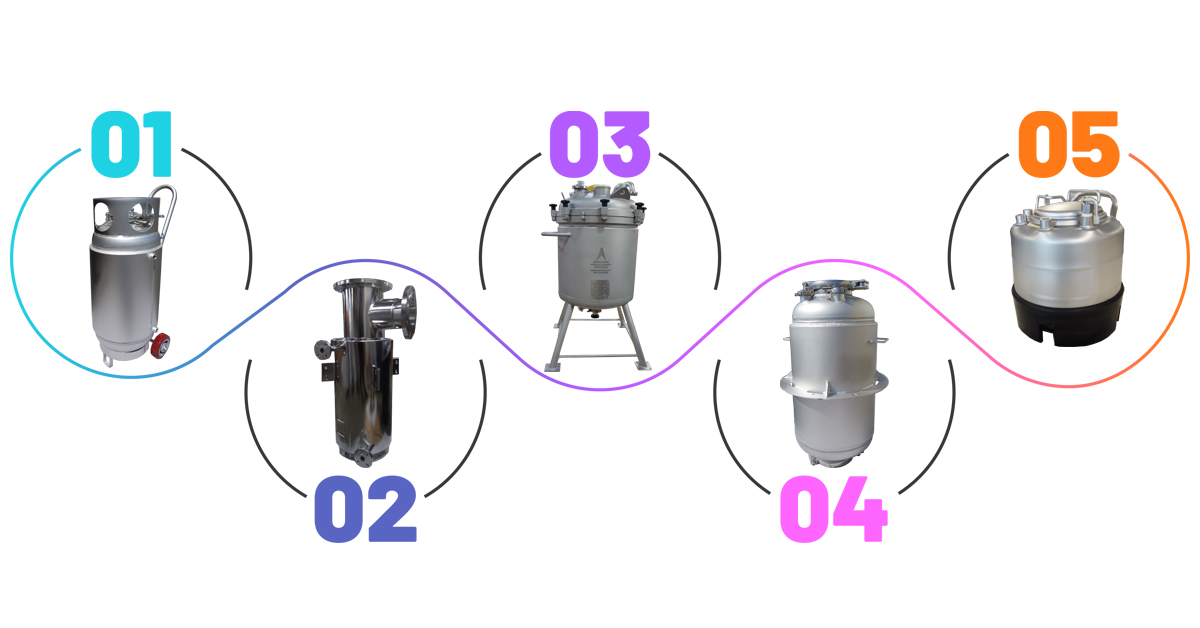

When searching for a new Cannabis Processing or Extraction vessel equipment supplier, ask these five questions:

- Does the vessel supplier have experience with the types of processing equipment you require to produce your product? The vessel manufacturer should have experience with CBD and Cannabis processing vessels, extraction tanks, mixing tanks and separating vessels. For complex applications or scale solutions, you may need to consult a process engineering firm to solve your CBD process challenges.

- If you aren’t sure about the type of equipment you need, do you have access to collaborate with the vessel manufacturer’s application and engineering team to discuss your challenges? There continues to be numerous start-ups for new types of CBD products, and that equipment can come at a high cost. There may be value in a collaborative meeting with application specialists to vet your project and costs and learn more about equipment offerings.

- What types of processes and components does the vessel manufacturer offer for the hygienic design? The FDA and other regulatory agencies will set the standard for sanitation and hygienic design in the CBD / Cannabis processing industry. Your vessel manufacturer must have offerings and experience with COP (clean out-of-place) sanitation and CIP (clean-in-place) sanitation components. They must also meet RA (roughness average) requirements and offer mechanical and chemical finishing services to meet the hygienic requirements set by regulatory agencies.

- Does the vessel manufacturer hold ASME certification? Most local and state laws require vessels designed at 15 PSI and higher to be ASME certified. Moreover, ASME requirements are also in material specifications, construction, and welding qualifications. Determine all industry compliance accreditations, including FDA, 3-A, CRN, PED and BPE.

- Does the vessel manufacturer provide the testing and documentation services you need for your Cannabis or CBD processing vessel? There are significant testing, certifications, and documents requirements for all US and global accreditation programs. An experienced quality assurance department will provide trained and certified personnel; and assure the proper procedures and documentation to support your vessel.

Apache Stainless is a manufacturer of sanitary, highly engineered, ASME pressure vessels for a multitude of industries, including cannabis processing, pharmaceutical, health and biopharma. We have served the Cannabis and CBD processing industry several years with processing tanks, hydrocarbon extraction tanks, mixing tanks and separating vessels. We also design and manufacture vessels with Canadian Registration Numbers (CRN) for all Canadian provinces. We have all Stainless ASME certified manufacturing facility with custom capabilities including heat exchange surfaces, agitation, CIP (clean-in-place) componentry and controls. Apache has an in-house quality and compliance team to provide all testing and documentation requirements.

Visit Small Vessels for more information.